Skidtube with Standard Wearplates Fits LH or RH

Part Number: D135-751-011

Aircraft Models: Airbus - EC135

- In stock

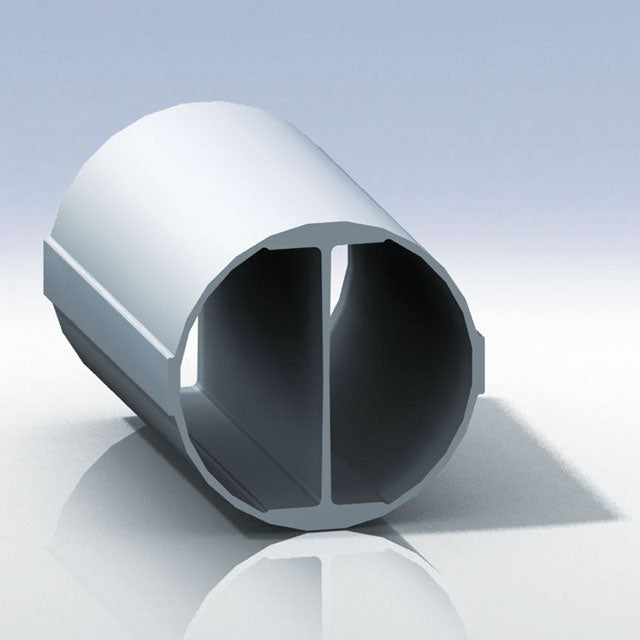

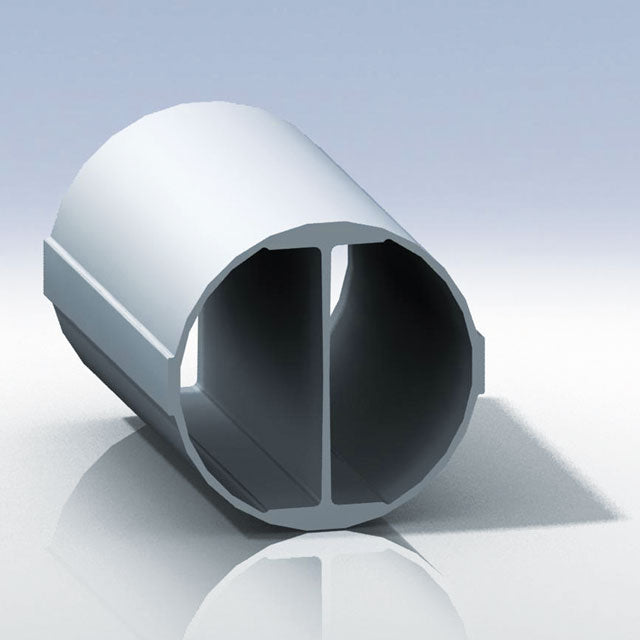

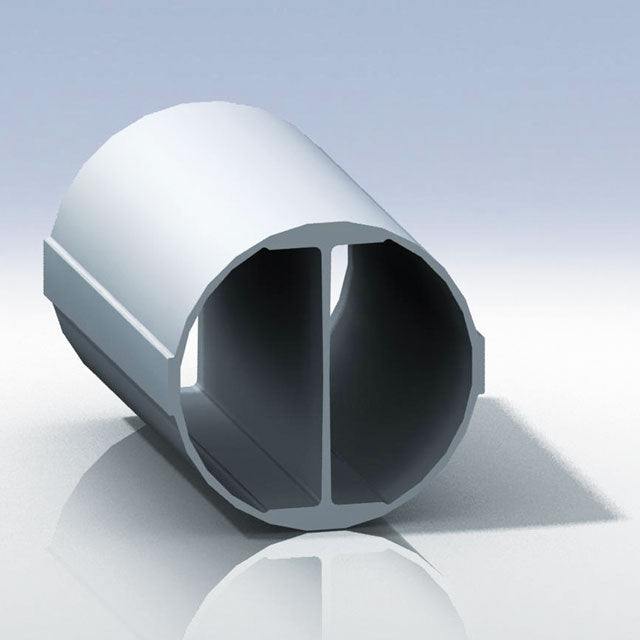

We believe that conventional skidtubes are under-designed for the types of landings most helicopters encounter. Conventional skidtubes are ill-equipped to face the critical loading conditions encountered when landing on uneven ground. Under these conditions, simple round tubes tend to puncture, dent and bend because they cannot maintain their shape. DART Aerospace's revolutionary patented Round-I-Beam™ technology combines the conventional round tube with the strength of the I-beam made from 6061-T6 aluminum. In DART Aerospace skidtubes, the central I-beam web absorbs most of the impact on landing so the tube maintains its integrity. Even with the addition of a central web, the weight is comparable to that of conventional skidtubes. The wearplates are installed with a corrosion resistant compound between the skidtube and wearplate (no gaskets or sealant required). Comes standard with full-length stainless steel tungsten carbide welded wearplates.

*Comes with 4 full-length Stainless Steel wearplates & 2 additional wearplates at the saddle locations. Saddle wearplates and AFT most wearplate are tungsten carbide welded. Pre-drilled for compatibility with Bristol WSPS (p/n 965-19500-101) Skid Deflector. Can be made compatible with DART (Apical) Tri-Bag Float System p/n 644.1801/1802/1806/1807/1808/1809 when installed with D135-751-101 & 644.1805. Must be installed with L321M1003102 FWD crosstube and L321M1002101 AFT crosstube.

Couldn't load pickup availability

Key Features

- Patented I-Beam construction

- Includes full-length stainless steel wearplates with tungsten carbide welds

- LH/RH interchangeable

- Made from 6061-T6 aluminum

- Installs with OEM saddles

- Pre-drilled for float compatibility

Key Benefits

- 10 times more resistant to crushing due to I-Beam technology

- Full-length stainless steel wearplates with tungsten carbide welds

- Reduced inventory of spares (tubes are not handed)

- Easy wearplate installation and removal for inspection/replacement

- Compatible with OEM Crosstubes & saddles

- Repairable/weldable

Approvals

| Approval type | Authority | Reference number | Aircraft approved | Description |

|---|---|---|---|---|

| PMA | FAA - USA | PQ1886NM Supplement 67 | EC135 | Approved replacement |

| STC | EASA - Europe | EASA.IM.R.S.01278, Rev 1 | EC135P1/EC135P2/EC135P2+/EC135T1/EC135T2/EC135T2+ | D135-751 Approved OEM Replacement Skidtube |

| STC | FAA - USA | SR01709SE | EC135P1/EC135P2/EC135P2+/EC135T1/EC135T2/EC135T2+ | D135-751 Approved OEM Replacement Skidtube |

| STC | TCCA - Canada | LoA RDIMS-9661680-v1 | EC135P1/EC135P2/EC135P2+/EC135T1/EC135T2/EC135T2+ | Installation of Skidtube and Skidtube Extension |

OEM Cross References

N/A

External Warning

N/A

Prerequisite

N/A

Compatible With

Bristol WSPS kit: 965-19500; OEM Crosstubes; DART Tri-Bag Floats: 644.1801/1802/1806/1807/1808/1809 (requires D135-751-101 Skidtube Extension Kit and 644.1805 Skid Extension Kit).

Not Compatible With

Aerazur Floats; Skidtube Extension: 644.1803

Flight Restrictions

N/A

Installation Time

2 hrs

Dimensions And Weight

- Length: N/A

- Width: N/A

- Weight Display: 24.50 lbs / 11.20 kg

Load Capacity And Volume

- Volume: N/A

- Load Capacity: N/A

Technical Documentation

Downloads

N/A